For Specialized Cold-Headed Fasteners

FOR 81 Years: 1943-2024

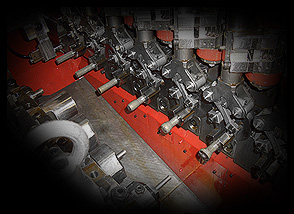

“Net Shape” It is the engineering design concept that drives our equipment. Vico’s assortment of the most accurate, productive and reliable progressive headers includes models made by world leaders such as Asahi Sunac, National Machinery, Sakamura, Nedschroef and Asahi Okuma. These multistation forming machines with 4,5 and 6 forming dies provide us outstanding flexibility with high production abilities. With the means to cut off 15-32mm wire and with forming tonnages up to 550 tons, “Net Shape” designs of even the most highly toleranced precision are realized.

Efficient and precise turning capabilities at the highest possible level of quality. If your piece requires metal cutting we’re prepared to do so with maximum productivity. Utilizing one of our many multi-spindle Acme or Euroturn collet chuckers or Miyano CNC lathes we will employ our experience and expertise in order to get the job done in the most effective method. Vico’s machining engineers strive to reduce cycle time in order to keep our cost down. Utilization of automation, high quality tooling and quick change over techniques minimize the typically high cost of secondary machining.

Vico Products has a strong focus on engineering capabilities, which are an essential component of their product development process. Their team of highly skilled engineers utilizes state-of-the-art software and tools to design and develop innovative products that meet the highest industry standards. Vico Products’ engineering capabilities include computer-aided design (CAD), finite element analysis (FEA), rapid prototyping, and testing and validation. Vico Products is able to provide customers with high-quality and reliable products that are tailored to their specific needs.

Copyright © Vico Products | Designed By Engaged Web Designs